Full Service Fulfillment Company

Our mission is to make your projects, concepts, designs, and products come to the marketplace as complete, individual packages within the time and monetary framework that you would expect from your best suppliers.

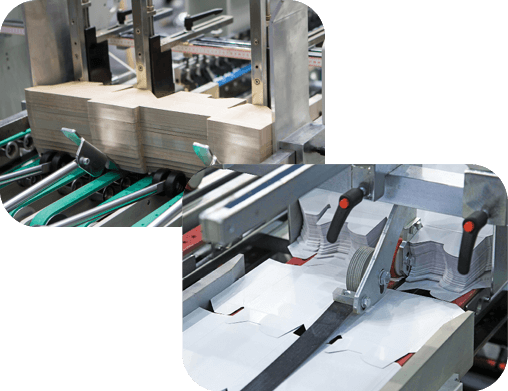

Madcar is a turnkey provider of contract packaging, assembly, fulfillment, and distribution services. We’re certified for Good Manufacturing Practices for Cosmetics, and FDA inspected and registered for the Secondary Packaging of OTC Drugs and Food and Food Supplements.

Contact Us

Success is about more than how quickly you can “print & ship.” For every project that comes through our doors—the Madcar team offers the kind of unique insights, deep expertise, and attention to detail that can take your project from good to great.

- Schedule Your FREE Consultation Today

- Speak to a Customer Service Representative

- Request a Price Quote for Your Project

- Learn More About the Services We Offer

Whether we’ve done business together already or you’re looking to begin a new relationship with Madcar, our promise remains the same—”Give us time and we’ll give you value.”